Kraft Paper

Kraft paper is made from at least 80% sulfate wood pulp. It is course and exceptionally strong, making it well suited for a packaging substrate.

What is the difference from normal paper?

Made from natural wood sources, its manufacturing process involves a higher ratio of sulphur compared to conventional paper. This helps strengthen its fibres and cellulose, making it stronger than recycled paperboard. Additionally, this is what gives the paper its name, as “kraft” means “strong” in German.

Advantages:

– Kraft paper packaging is the most cost-effective packaging option;

– Kraft paper packaging has a wide range of uses in the commercial sector;

– Kraft paper boxes have better graphic printing capabilities;

– Kraft paper boxes are easy to personalize and customize.

Impacts for the environment:

Kraft paper is made from wood pulp, a renewable resource, which makes it more sustainable than other packaging materials. Additionally, kraft paper is biodegradable and can be recycled, which means it has a lower impact on the environment

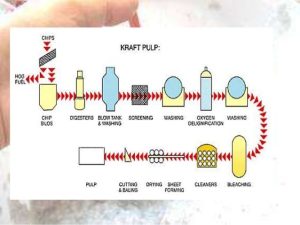

Manufacturing process:

Materials preparation: According to the quality technical requirements of fine kraft paper, we choose the process of softwood and hardwood mixing pulp.

– Pulp cooking and bleaching:

The pulp of fine kraft paper is required to have less coarse fiber bundles and stable color, and it has high-quality requirements for cooking and bleaching processes. It is well known that there is a big difference in the performance of cooking and bleaching between softwood and hardwood. If the pulp production line can separate pulping of softwood and hardwood, the cooking and bleaching of softwood and hardwood alone can be preferred.

– Beating

To improve the paper strength of fine kraft paper, optimizing the pulping process is an important measure. In general, to improve the physical strength of the paper, the uniformity, and flatness of the paper, it is necessary to appropriately increase the beating degree of the pulp, while maintaining its good air permeability and low tightness, the degree of beating should not be too high.

– Kraft papermaking

The breathability, tightness, and smoothness of the paper are related to the press production process. The pressing reduces the porosity of the paper, thereby reducing the paper permeability and suction height, and improving the tightness; the air permeability and tightness of the paper are rapidly increasing with the increase of the pressing pressure and the pressing time. The physical strength of the paper can be improve